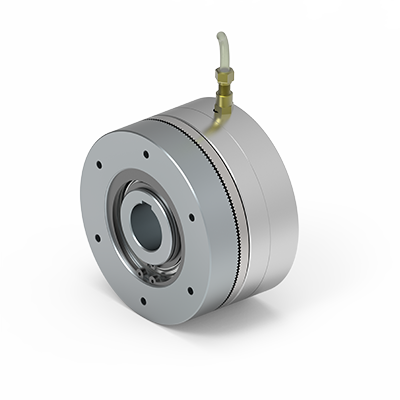

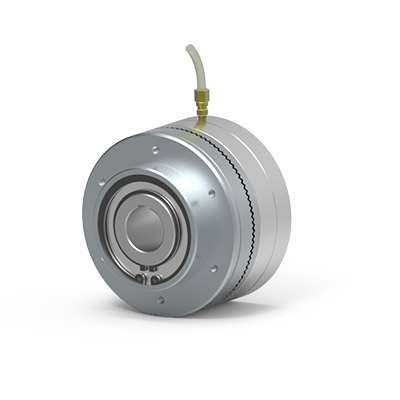

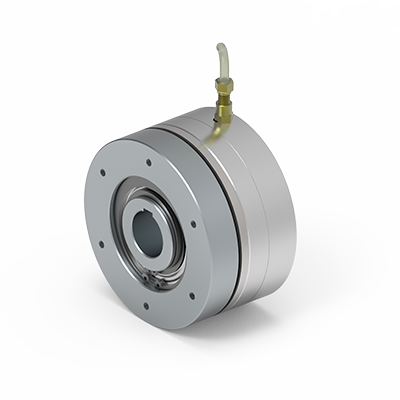

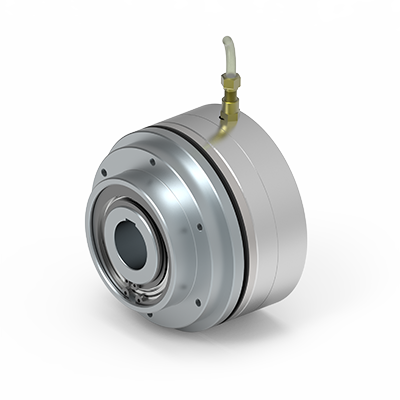

Pneumatic clutches

Pneumatic clutches are used to connect or disconnect mechanical parts (motors, conveyor belts, shafts, gears, pulleys, flywheels) using compressed air. When the air enters the clutch, it causes the movement of mechanical components that make it possible to connect or disconnect with other parts of the machine. Depending on the application, the coupling can be achieved with friction materials or teeth. This technology is widely used in industries such as automation, packaging, and manufacturing..

Telcomec’s pneumatic clutches are designed to operate dry and powered by 6 Bar compressed air*.

Quick response times

Pneumatic clutches can perform very rapid operations, a characteristic that’s essential in high-speed production lines.

Ease of control

High efficiency and reliability in maintaining torque

Reduced maintenance

The cleanliness of compressed air and the simplicity of the design minimise the need for frequent maintenance.

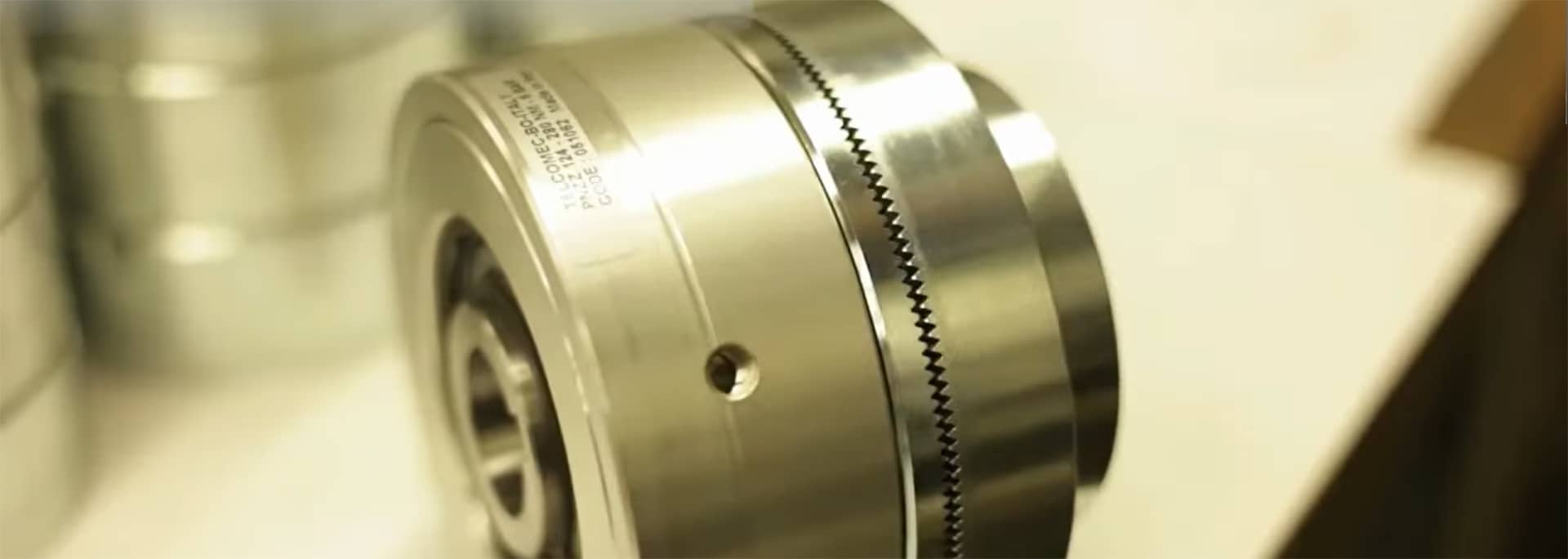

Pneumatic tooth clutches

Torque from 50 Nm to 6500 Nm

Speed: 1200-3500 rpm

High torque transmission capacity

Precision alignment with reduced risk of slipping under load

Pneumatic friction clutches

Torque from 5 Nm to 370 Nm

Speed: 1200-3500 rpm

Gradual start and stop capability

Quiet operation with reduced wear

*For use with hydraulic power, please contact our tecnhical department

Fields of application

- Packaging machines: for rapid opening and closing during automatic packaging processes.

- Automotive assembly lines: for rapid tool or part changes during assembly.

- Transport and logistics systems: for handling and securing loads.

Professionals' Members Area

If you are a professional and are interested in viewing technical drawings and videos of our pieces, to evaluate which is most suitable for your needs, SIGN UP for our restricted area.

Login