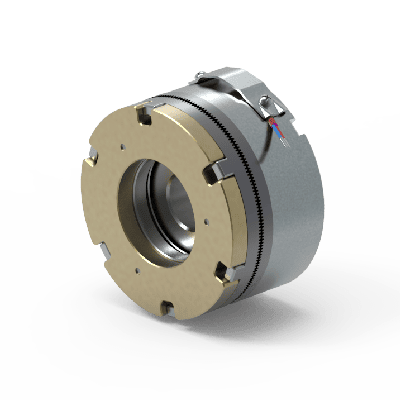

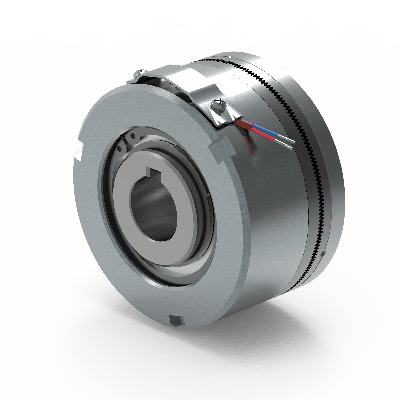

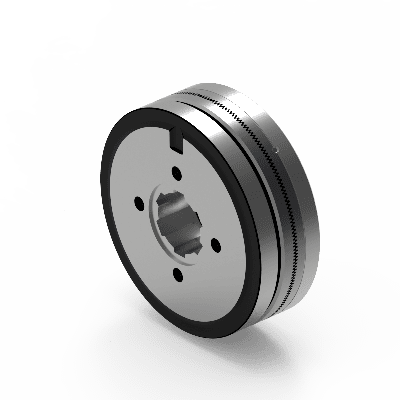

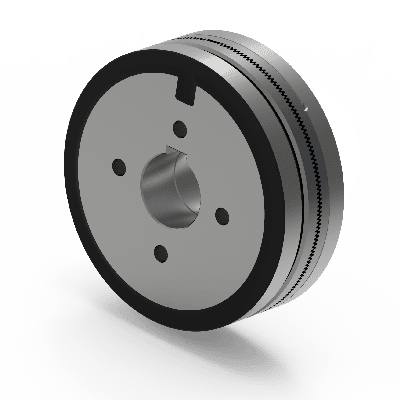

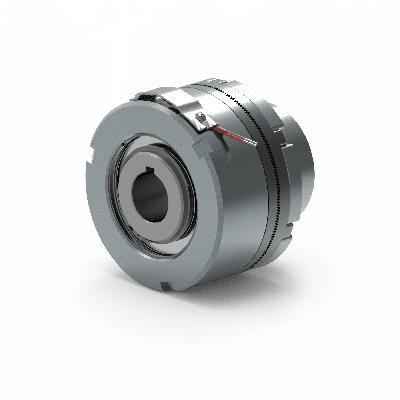

Electromagnetic tooth clutches

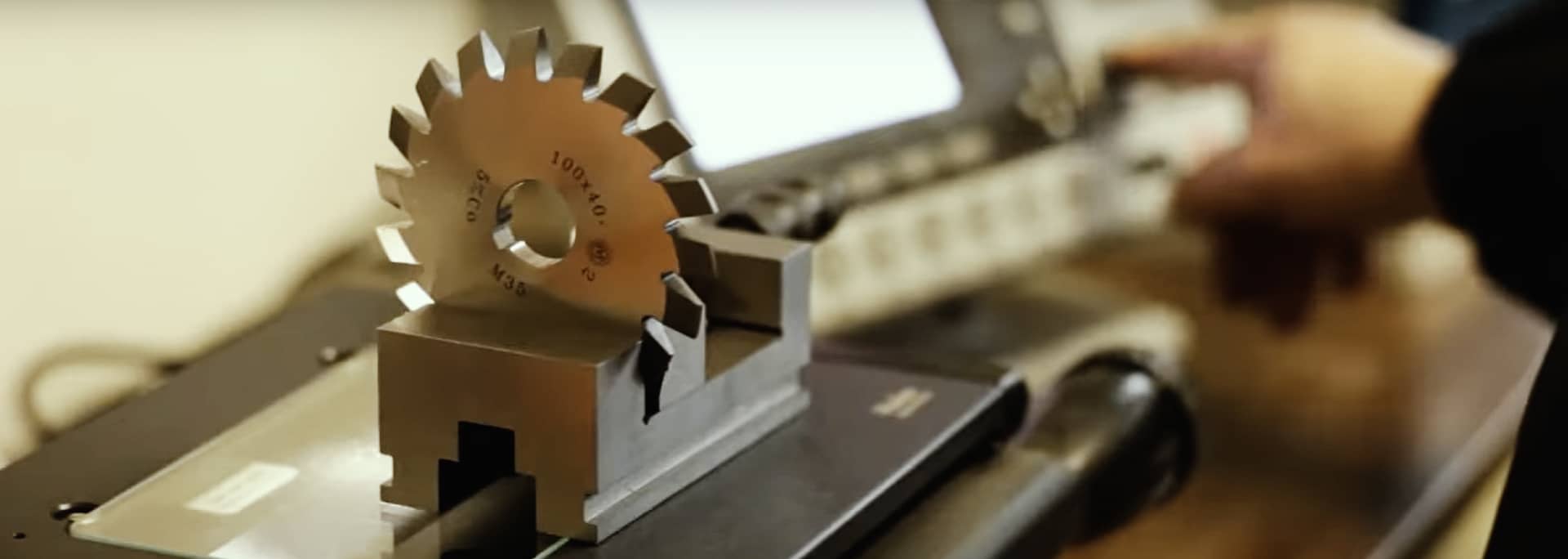

Electromagnetic tooth clutches operate by using a magnetic field to engage the clutch. This type of clutch is particularly useful in applications that require a rapid and precise coupling between shafts, without the need for relative movement between the components connected during engagement.

Electromagnetic tooth clutches are, therefore, advanced technical solutions that are used in numerous industrial sectors, offering performance and reliability, even under heavy loads and intensive use, ensuring precise coupling.

Telcomec’s Electromagnetic toothed clutches are designed to operate both dry and oiled. For continuous 24-hour operation, adequate ventilation is highly recommended.

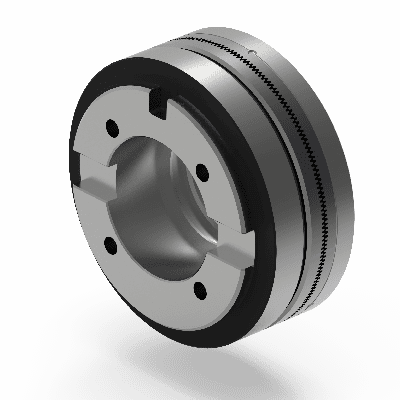

High power transmission

The direct contact between the teeth makes it possible to transmit high levels of power, higher than those of friction clutches, without the risk of slipping.

Quick coupling

Once the magnetic field is activated, the coupling is almost instantaneous, making these devices suitable for operations that require frequent starts and stops.

Electrical control

The engagement and disengagement of the clutch are electronically controlled, allowing for easy integration with automated control systems.

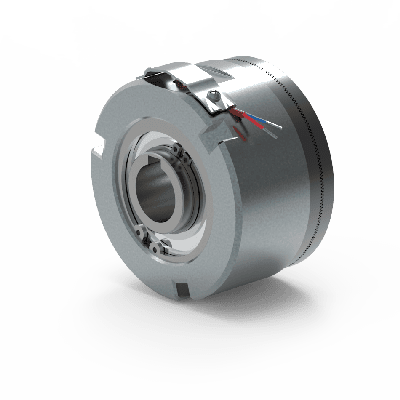

Pulsed current electromagnetic tooth clutches

These clutches require electrical current to engage. The electromagnetic field generated by the application of electrical current allows the teeth to interlock and transmit power. They’re useful in applications where it’s essential to be able to actively control when and how power is transmitted between two parts, as in automated production lines.

The lack of contact between the toothed surfaces during the disengagement phase reduces wear on the device and helps to eliminate residual torque.

Torque from 20 Nm to 18,000 Nm

Speed: 600-5000 rpm

Standard tooth profile: trapezoidal

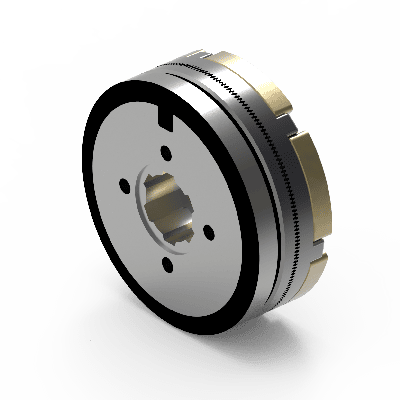

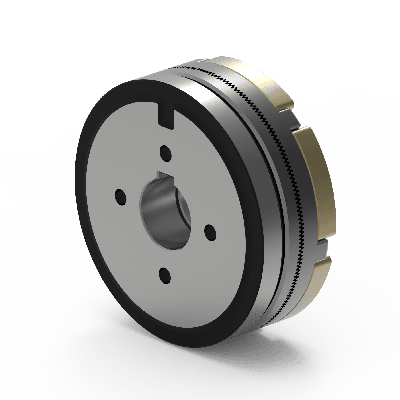

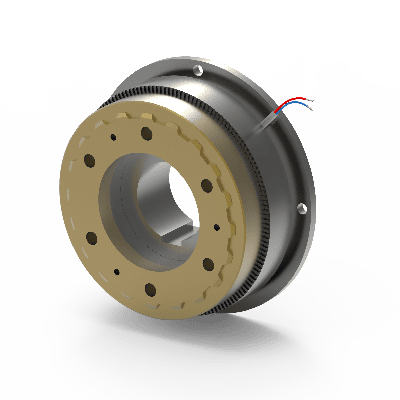

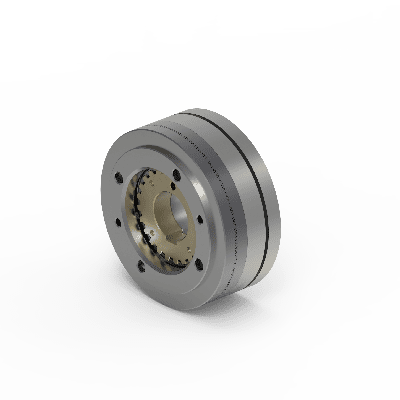

ELECTRICALLY RELEASED TOOTH CLUTCHES

Electrically released clutches require the interruption of electrical current to disengage. Under normal conditions, the teeth are in contact and power is transmitted through spring pressure. If the electrical current is interrupted, like in an emergency or in the event of a malfunction, the transmission also stops. This type of clutch is particularly useful in applications where the teeth remain engaged for most of the day, preventing the constant heating of the electrical coil.

Torque from 30 Nm to 950 Nm

Speed: 1000-4000 rpm

Standard tooth profile: triangular

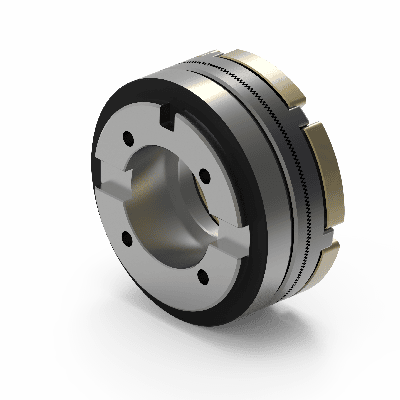

Tooth profiles

Electromagnetic toothed clutches can be manufactured with teeth of different shapes, which must be specified at the time of ordering:

- Trapezoidal teeth: limited peripheral backlash, stationary engagement.

- Triangular teeth: zero backlash during coupling, stationary engagement

- Anticlockwise and clockwise saw tooth profiles: profiles at different angles, stationary or low-speed engagement.

- Tooth profiles for fixed point engagement: insertion of teeth at predetermined angular positions, low-speed engagement.

For further details, please refer to pages 12-13 in our general catalogue or contact our technical office to discuss the most suitable configuration for your application.

Fields of application

- Industrial machinery: used in presses, rolling mills, cutting machines, and other industrial applications that require a reliable and high-power connection.

- Electric vehicles: can be used in transmission systems for electric vehicles to manage the coupling between electric motors and transmission systems.

- Robotics and automation: in robotics, they can be used to ensure precision movements and to handle varying loads.

Professionals' Members Area

If you are a professional and are interested in viewing technical drawings and videos of our pieces, to evaluate which is most suitable for your needs, SIGN UP for our restricted area.

Login